2025.06.26

Lead smelting is a crucial step in the recycling of lead-containing materials such as spent lead-acid batteries. However, lead smelting processes produce hazardous waste gases, including lead dust, sulfur dioxide (SO₂), nitrogen oxides (NOx), and other pollutants. These emissions pose serious environmental and health risks if not properly controlled.

With increasingly stringent environmental regulations worldwide, lead smelting companies face mounting pressure to achieve standard-compliant emissions. This article explores how the industry can effectively control waste gas emissions, highlighting key technologies and solutions, and showcases how RE TECH's advanced equipment helps smelters meet and exceed emission standards.

Environmental protection agencies in many countries have set strict limits on lead and sulfur compounds in waste gas from smelting operations. For example:

The U.S. EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP) regulate lead emissions stringently.

China’s GB 25467-2010 standard specifies maximum allowable emissions for lead smelting pollutants, including lead dust and SO₂.

The European Union’s Industrial Emissions Directive (IED) mandates continuous emission monitoring and low emission limits.

Complex pollutant composition: Lead smelting gas contains both particulate (lead dust) and gaseous pollutants (SO₂, NOx), requiring multi-stage treatment.

Process variability: Fluctuations in feedstock and smelting conditions affect emission levels and treatment efficiency.

High temperature and corrosive gases: Treatment systems must withstand harsh operating environments.

Integration with production: Pollution control must not impede smelting efficiency or increase operational costs excessively.

Electrostatic precipitators (ESPs) use electric fields to capture lead dust particles from exhaust gas with high efficiency (often >99%). Bag filters complement ESPs by filtering fine particulate matter. RE TECH offers high-performance ESP systems tailored for lead smelting plants, ensuring efficient dust capture and long-term reliability.

FGD systems chemically remove SO₂ from exhaust gas via wet or dry scrubbing processes. Wet limestone scrubbing is common, converting SO₂ to gypsum, a usable byproduct. RE TECH integrates advanced FGD units into their smelting solutions, providing stable SO₂ removal that meets or exceeds regulatory thresholds.

SCR technology reduces NOx emissions by injecting ammonia or urea into flue gas over a catalyst. Although NOx emissions are generally lower in lead smelting than other metal smelting, SCR remains vital in some operations. RE TECH can supply SCR systems as part of comprehensive emission control packages.

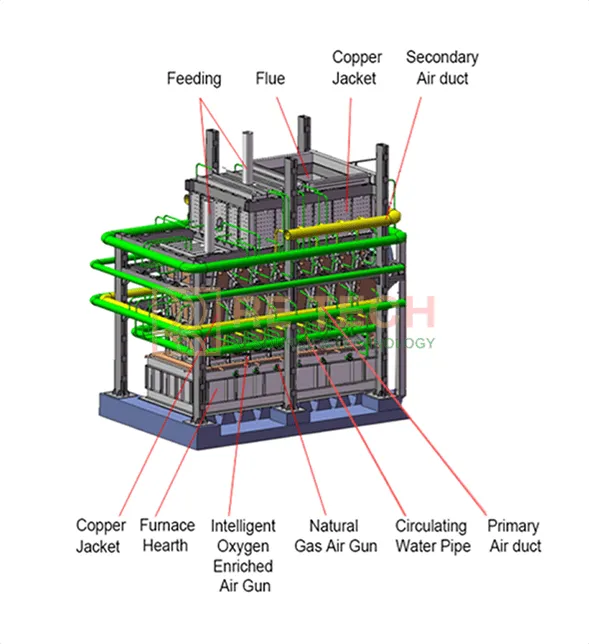

OSBF technology improves combustion efficiency and reduces excess air, lowering the volume of flue gas and pollutant formation. The enhanced furnace atmosphere leads to less sulfur and lead emissions. RE TECH specializes in OSBF furnaces, combining energy efficiency with lower emission profiles.

Combining dust removal, desulfurization, and denitrification into a compact, automated system ensures consistent compliance. RE TECH provides turnkey EPC (engineering, procurement, and construction) solutions that integrate these components seamlessly, customized for each client’s capacity and feedstock.

RE TECH's core competencies lie in developing and delivering state-of-the-art equipment for non-ferrous metal recycling, particularly lead smelting plants, with a strong emphasis on environmental performance.

Their OSBF furnaces are designed to maximize lead recovery while minimizing emissions through precise oxygen enrichment and furnace atmosphere control.

Their customized flue gas treatment systems incorporate ESP, FGD, and SCR technologies, tailored for optimal pollutant capture.

They provide turnkey EPC solutions including battery crushing, sorting, smelting, refining, and emission control, enabling customers to meet global emission standards efficiently.

RE TECH's close collaboration with research institutions ensures continual innovation in cleaner production technologies.

Achieving standard emission of lead smelting waste gas is a multifaceted challenge involving advanced pollution control technologies, process optimization, and system integration. With tightening environmental regulations, smelting companies must adopt comprehensive solutions to protect the environment and ensure operational sustainability.

RE TECH, with its proven expertise in OSBF furnace technology and integrated flue gas treatment systems, stands as a trusted partner for smelters worldwide seeking to meet emission standards while maintaining production efficiency.

Navigation

Equipment

Mob. / WhatsApp: +86 182 0740 9461

+86 137 8726 1326

Tel.: +86 731 8540 4716

Email: info@remetalrecycling.com

Skype: pbjoyz

Address: Building.10, Liandong U Valley Industrial Park, Yuelu District, Changsha, Hunan, China 410036

Upload your raw material chemical composition to get a quick proposal

Want to know equipment quotation or project investment, please contact us