Oxygen Enriched Side Blown Furnace Description

The furnace design of the RE-type oxygen enriched side blown furnace is a result of years of research and development led by the experts of the company from Central South University and nonferrous metallurgy industry. The team behind the design has extensive experience in the non-ferrous metallurgical industry. The very first patent on the oxygen-enriched side-blown furnace process was obtained by Liu Wei, the founder of the company, in 2014. Since then, the company has been dedicated to continuous innovation and R&D to respond to the changing demands of the industry. The process design and furnace design have been constantly improved, resulting in the acquisition of more than 40 patents.

The oxygen enriched side blown furnace plays a vital role in numerous industries, and this particular furnace type has garnered significant attention owing to its outstanding performance. It has proven to be a game-changer, not just in terms of economic benefits but also with regards to environmental protection,energy-saving,efficiency,safety and stability. Its popularity has only soared over the past decade, with newly-built smelters widely incorporating this furnace type.

OESBF stands for Oxygen Enriched Bottom Blowing Smelting Process, a method used in metallurgy to enhance the efficiency of the smelting process. This technique involves blowing oxygen into the molten metal from the bottom of the furnace, which improves the overall reaction kinetics and efficiency of the smelting process. The Oxygen Enriched Bottom Blowing Smelting Process is employed to produce high-quality steel and other metals with greater precision and lower costs.

Technical Specifications

| Parameter | Range |

|---|---|

| Daily Capacity | 120 – 1200 tons |

| Operating Temperature | 1100 – 1500°C |

| Furnace Type | Side-blown, oxygen-enriched |

| Fuel Options | Coal, coke, natural gas, or mixed fuels |

| Reductant Options | Carbon sources including coal, coke, charcoal |

| Automation | Full DCS control, remote industrial network support |

| Environmental Control | Waste heat boiler + flue gas purification, dust < 50mg/Nm³ |

| Lifespan | Furnace: 10–15 years; Copper components: 5–7 years |

| Maintenance Interval | 6–12 months (depending on usage) |

Capacity per day: 120ton~1200ton

Design Features

Oxygen Enriched Side Blown Furnace Design

Copper Jacket And Copper Nozzle Design

Furnace Hearth Design

The Unique Design of Flue and Waste Heat Boiler Ensures

Highly Automated

Patented overall furnace design, the same area of greater capacity, saving investment in the furnace construction and civil construction.

Patented design copper jacket and copper nozzle, long life of the whole furnace, less maintenance requirement

Patented furnace hearth design, longer service life.

The unique design of flue and waste heat boiler ensures that the flue gas stays in the high temperature area for no less than 2 seconds, and the dioxins and carbon monoxide in the flue gas are fully combusted, reducing the dioxins in the flue gas and lowering the dust rate.

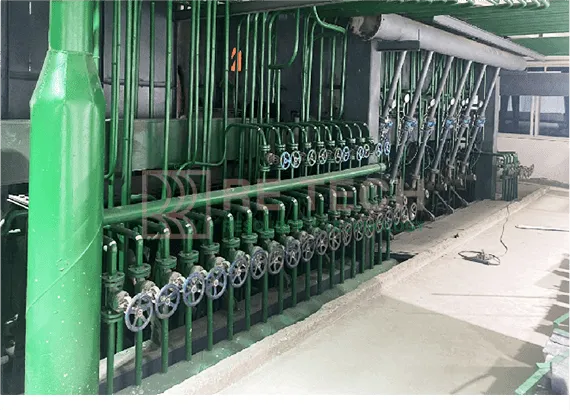

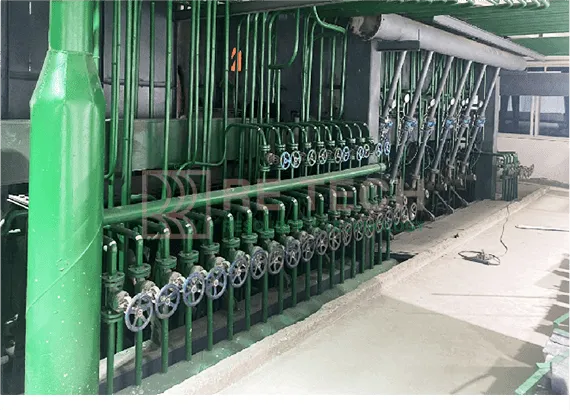

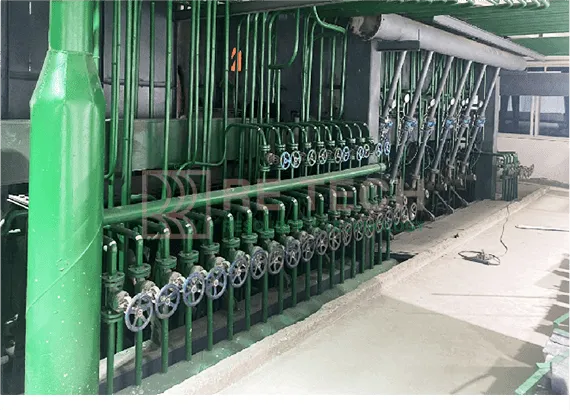

Highly automated, all charging, gas distribution, furnace condition monitoring, smoke monitoring and subsequent environmental protection facilities are controlled by the DCS control system in the central control room, and the control system is equipped with a remote industrial net gate, which can realize remote control and mobile control.

Why Choose RE Oxygen-Enriched Side-Blown Furnace?

Energy Efficiency & Cost Savings: Advanced oxygen-enriched smelting reduces fuel consumption by up to 25%, lowering operational costs significantly.

Environmentally Friendly: Optimized flue design ensures complete combustion of harmful gases, reducing dioxins and dust emissions.

High Metal Recovery: Achieve up to 98% metal recovery with minimal residual lead or copper in slag.

Operational Flexibility: Adaptable to various fuels and reductants, allowing cost optimization based on regional availability.

Safety & Automation: Fully automated DCS control with remote monitoring ensures safe operation with minimal manual intervention.

Patents

Results / Patents

Type

Application Number

Status

Patent Number

An oxygen lance of side-blowing furnace and the side-blowing furnace

utility model

2021225608609

protection period

CN216080947U

A side-blowing furnace for oxygen-enriched molten pool smelting

utility model

2021202373238

protection period

CN214620642U

Operational Advantages

Flexible selection of fuel and reductant agents according to regional availability and price for different resources,good for cost control

High metal recovery rate, low lead content in slag, environmentally friendly

Wide application, mature process, high safety factor, convenient operation

Adopt low temperature melting, low operating cost and low dust rate

Applications

Lead recycling

Copper Smelting

Nickel Ore Processing

Slag & Sludge Recovery

Copper Refining

Dust & Ash Processing

Jul. 28, 2025

Jul. 28, 2025

Navigation

Equipment

Mob. / WhatsApp: +86 182 0740 9461

+86 137 8726 1326

Tel.: +86 731 8540 4716

Email: info@remetalrecycling.com

Skype: pbjoyz

Address: Building.10, Liandong U Valley Industrial Park, Yuelu District, Changsha, Hunan, China 410036

Upload your raw material chemical composition to get a quick proposal

Want to know equipment quotation or project investment, please contact us